Smart Factory Monitoring System

- PRODUCT

- Smart Factory Monitoring System Notice: Undefined offset: 3 in /home/host/rozetatech/www/html/_skin/layout/inc_navigation_middle.php on line 86

Smart Factory Monitoring System

SMART FACTORY MONITORING SOLUTION, PLC Sheriff

PLC(Programmable Logic Controller) System works like the main CPU of a computer in a factory automation system.

Factory robots are controlled by the program of PLC or NC.

In fact hundreds of PLCs have optimized plant automation to increase productivity and efficiency.

However, frequent business process changes require the consequential adjustments of PLC program.

PLC market conditions have been described as the closed one which has been led by a few major companies like Mitsubishi, Siemens and Rockwell.

RozeAI’s PLC System saves data automatically whenever its program is changed, informs the process variation to managers instantly and recovers the previous PLC data to normalize the process.

ADVANTAGES

-

Automatic data backup

-

Monitoring

-

Prompt restoration

-

Anti-virus

-

Loss minimization

-

Convenient management of controlling program

-

Process warning with changes

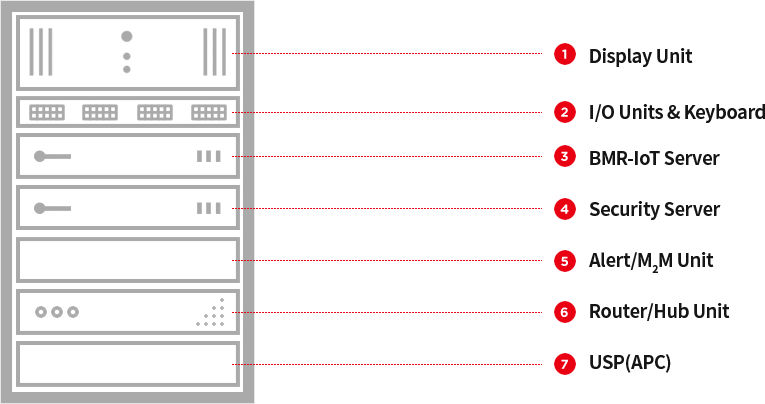

PRODUCT COMPOSITION

HOLDING TECHNOLOGY

-

01

DPBI/SIEM/APT/ ASCII Strcmp Source analysis security technology

-

02

DPBI/SIEM/Sandbox/ Binary Validation Check security technology

-

03

IoT system that allows real time data collection from production facilities

-

04

Real time data transmitting system using UDP which connects PLC and the development system

-

05

Distributed IoT control system at each stage of the workflow

-

06

Distributed IoT control system at each stage of the workflow

-

07

Auto-Backup/ Recovery system & DPBI(Deep Protocol Behavior Inspection)/Protocol Tracing technology

-

08

IoT RF Alert system & RF Amplifier & Multiprocessing technology

FUNCTION AND CONFIGURATION

-

Load Security Server with PLC Security Solution

-

Load SBMR-IoT Server with PLC Back-up Solution

-

Load SBMR-IoT Server with PLC Monitoring Solution

-

Load SBMR-IoT Server with PLC Recovery Solution

-

Build Network Router/Hub equipment to control distributed PLC

-

Construct M2M equipment for additional IoT alert function

-

Build HDD for the second Back-up of the above solutions

-

Set up power stabilizer for the stable operation of the whole system

-

Commercialize the system after mounting on Rack-serve case

EFFECT OF APPLICATION

The special thing of RozeAI’s PLC System is the integration of these three functions – monitoring, management and backup/recovery.

We expect that our product will achieve first-mover advantage in market when it finishes testing in a Korean mobile manufacturing company.

- Respond closely to urgent issues through pre-verification of production line risks and history management

- Contribute to improving company productivity when applied to automated production lines

- Securing cost competitiveness by reducing manufacturing costs

- Increase in productivity per unit

Technology spreading effect

Technology spreading effect

- Job creation through sales improvement, contribution to national/local finances

- Improve the image of a new model of creative economy and technology-leading city by launching technology-leading products

- Creation of new added value through next-generation product development plan based on MGPP (Multi-Generation Product Plan) concept

- Affects consumer prices by reducing product manufacturing costs

- Occurrence of factors that decrease product unit price through stable production line operation

- Affects the overall price level of society

Social effect

Social effect