RozetaTwin™

Digital Twin?

01 Twins implemented in digital space under the same conditions as reality

System or process software designed to detect, prevent, predict,

and optimize data from

real-world conditions

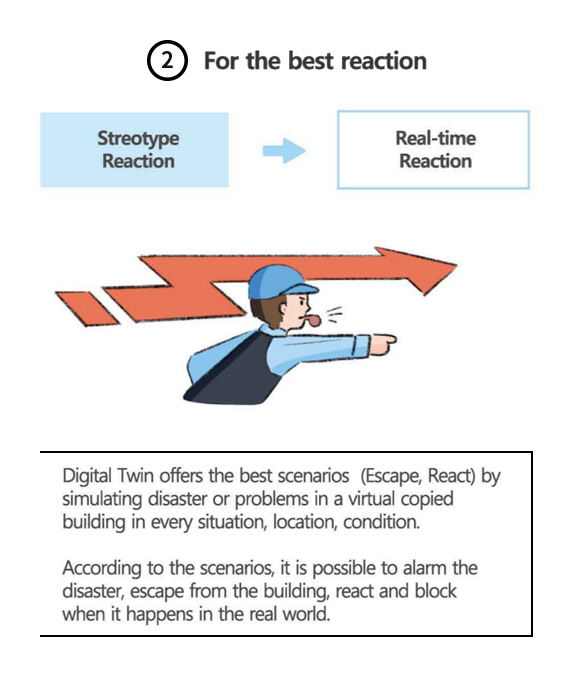

02 Optimal decision-making through simulation

Applied to various industries such as manufacturing, construction, medical care, distribution, transportation, and agriculture, emerging as a core technology in the 4th industrial era

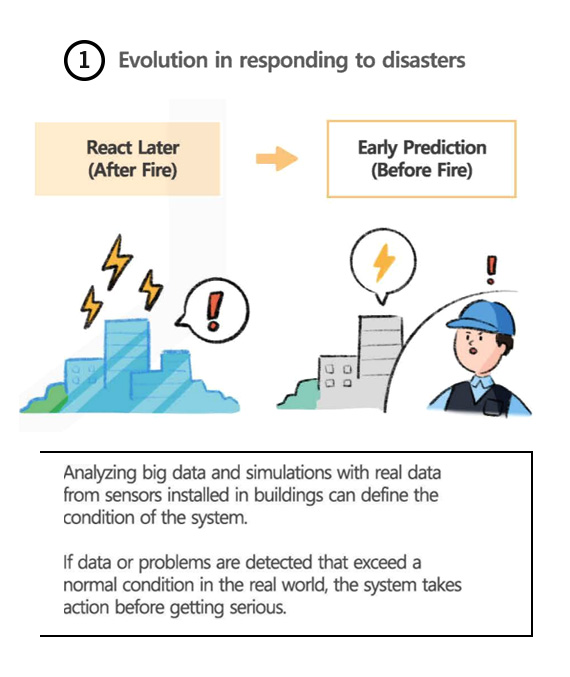

03 Innovation in Disaster Safety

In the event of a disaster, it is applied to the integrated disaster prevention system

or fire protection system as it can find the best response method and prevent it in advance.

Simulation → Optimized Solution

RozeAI’s Digitaltwin Technology

RozeAI, a Digital Twin technology-based System company

To complete a Digital Twin, it must be able to link with all sensors and other systems in the building,

so it is necessary to have high IoT technology and big data processing and analysis technology.

RozeAI is building an integrated disaster prevention system based on

Digital Twin technology for national institutions such as the Air Force Headquarters and power plants,

and was recognized for its global competitiveness and was selected as one of the 1000 National Innovative Companies,

KIST Family Company K-Club, and Ministry of Science and ICT Global ICT Future Unicorn Fostering Company

Through the Air Force Headquarters and Thermal Power plant projects, we have completed the development of the ‘Intelligent Integrated Disaster Prevention System based on Digital Twin Technology’ and are preparing to apply it to private buildings.

Development of digital twin-based integrated control and monitoring system

- Server and overall system for real-time data collection

- Non-fire alarm judgment by contrasting video information and fire monitoring sensor information – Accurate diagnosis eliminating misinformation

- Fire detection and firefighting facility operation, alarm generation and manager alarm notification

- Development of BIM/3D synchronization and real-time integrated monitoring of IoT sensors and image information

- Guidance on optimal evacuation routes to minimize casualties at fire sites

Development of fire detection sensor system

- Development of an integrated detection sensor through an interlock device capable of detecting all four types of heat/smoke/flame/gas (CO)

- Combined use of wired and wireless communication networks

- Data generating sensor system

DEVELOPMENT OF IMAGE-BASED FIRE DETECTION SYSTEM

- Flame and smoke detection using CCTV image artificial intelligence technology

- Long range (up to 5km) fire detection using thermal imaging cameras

- Position tracking judgment and statistical analysis/management of detected/detected information

- Video compression, storage, deletion, management and separate storage of fire detection images (Analytical data can be used to identify causes, etc.)

OTHERS

- Development of an HMI capable of converting existing analog firefighting facility transmission information to digital and transmitting firefighting situations in real time

RozeAI’s Digitaltwin Performance

-

Business Background Most of the fire detection systems of the Air Force are wired analog fire detection and firefighting equipment, and there is no integrated disaster prevention system that remotely monitors and controls firefighting facilities.

Accordingly, the Air Force promotes modernization of firefighting facilities using advanced technology.Business Purpose Prompt firefighting response, prevention of large-scale fire spread, minimization of human and material damage Progress - RozeAI’s ‘Digital Twin Technology-Based Integrated Disaster Prevention System’ is selected as a project (2020)

- 1st installation completed in OO Air Force unit (2021/12)

- Expansion of the integrated disaster prevention system to all units of the Air Force Headquarters (2023-2025)

Real-time CCTV image recognition IoT technology are used to minimize misinformation based on multi-sensor information to detect fire and smoke, generate an alarm, and build an [intelligent integrated disaster prevention system] that can provide evacuation guidance → prompt firefighting response and large-scale Prevention of fire spread, minimization of human and property damage

Starting with the 1st 「intelligent integrated disaster prevention system」, as the 2nd project, step-by-step establishment of an automated system* that integrates and manages major facilities such as mechanical/electrical facilities and lighting facilities in case of accidents and disasters such as fires

Digitaltwin-based Intelligent Integrated disaster prevention system

Digitaltwin-based Intelligent Integrated disaster prevention system

-

Complex sensing based on multi-sensor information

(image, heat, smoke, carbon dioxide, humidity)

Prevention of non-fire alarms/ Ensure Accuracy -

Building a system to collect/analyze data from all sensors

-

[Alarm generation - evacuation guidance - suppression]

Remote control of the response system -

Implementation of disaster predictive maintenance

through digitaltwin simulation

Existing fire response system VS. Digital twin fire response system

Existing system Digital Twin Integrated Disaster Prevention System Wired analog fire detector (heat / smoke)

Thermal imaging camera

Separate management system – electricity, gas

Alert-Breaking News Linkage System

Sprinkler interlocking system

Emergency exit, emergency exit information facilityIntelligent fire detector (heat, smoke, composite detector)

Wireless Detector - Repeater – Receiver

Alert-Breaking News Linkage System

Comprehensive control system – linked to sprinkler

Integrated management system – control of electricity, gas, chemicals, etc.

Thermal imaging camera

Camera for early detection of fire

Image analysis sensor

Escape guidance light

System for fire analysis

Fire analysis programWhen a fire is detected, it sounds an alarm and induces evacuation.

Linked to sprinklers.

Data provided by various devices can be checked in real time

No customized response scenario for each situationWhen a fire is detected, it automatically notifies the fire department and the manager, then guide evacuation in the safest direction

Modeling with data analysis provided by various devices to prevent fire in advance, such as automatic pre-blocking when out of the normal range during real-time check

Applying the optimal response scenario for each situation through digitaltwin simulation -

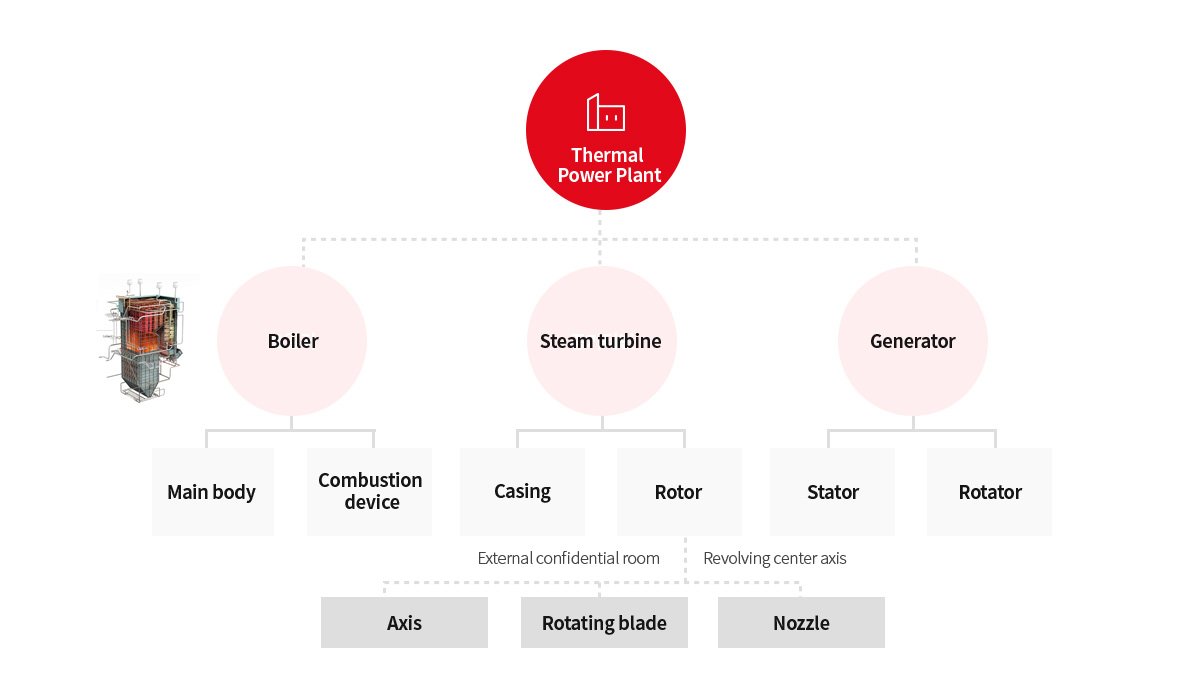

Business Background Development of a comprehensive fire protection system for visualized thermal power plants incorporating IIoT and Digitaltwin technology Business Period 2020.05.01 ~ 2024.04.30 (4years) Business Purpose To verify the digital twin fire protection system through a pilot project and introduce it to other power plants in the future

- Introduction of wireless fire IoT

- Fire big data, video analysis, FDS fire simulation verification

- Verification of comprehensive fire protection system based on 3D modeling and digital twinProcess 2020

Design Stage

2021

Development stage

2022

Installation/implementation Stage

2023

Test/Demonstration stage

2024

operation stage

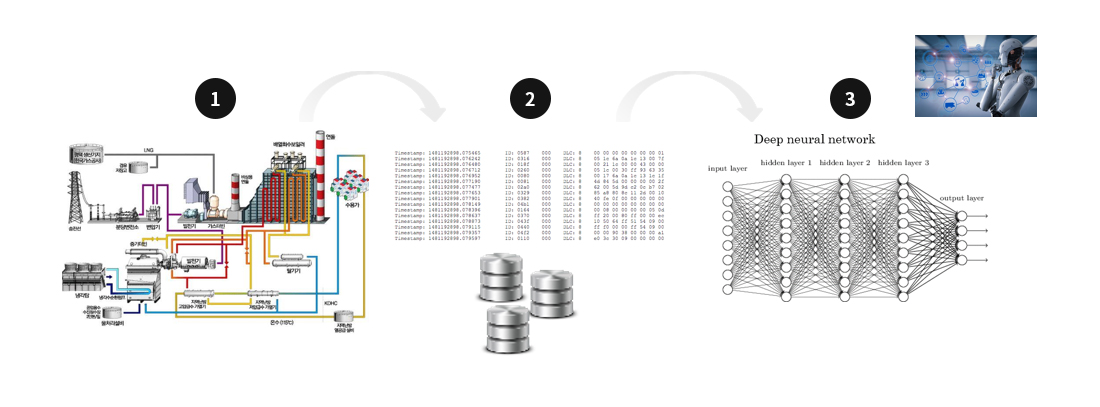

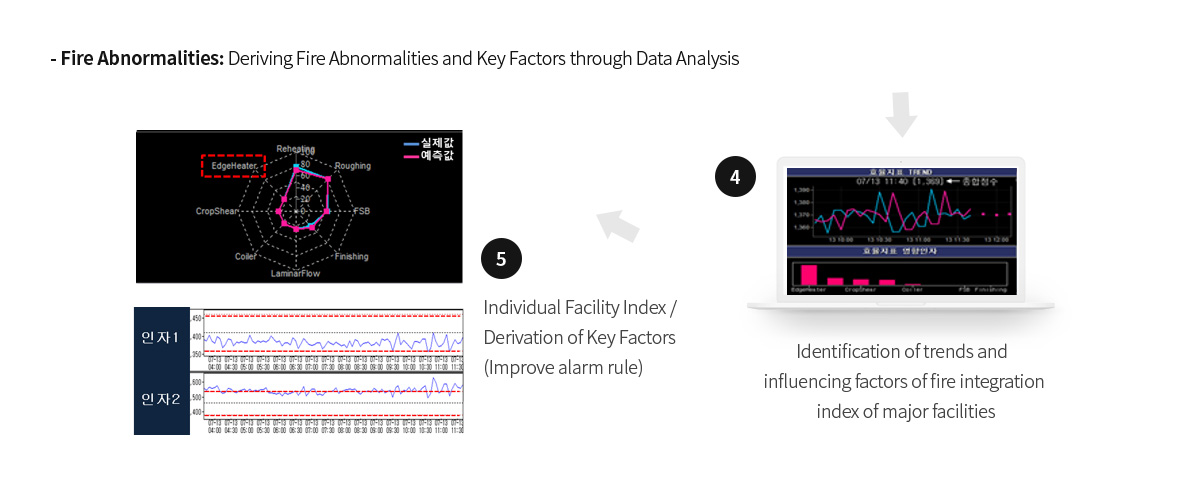

Development of fire big data and machine learning risk prediction model

1. Fire big data framework development and application

2. Comprehensive fire index and machine learning-based risk function and prediction model development by space/facility/fuel

3. System linkage: Realization of linkage with digitaltwin and dashboardFire risk index for major facilities of thermal power plants and each section

- Composite Index of Fire Protection by Major Parts of Thermal Power Plant

- Process for collecting and storing key facility status information Tag data

-

IoT Detector/Sensor

-

Repeater

-

Receiver

-

Primary collection device

-

IoT Bigdata Storage

Thermal power plant facility load and fire risk abnormal symptom model application

- Data collection: Collecting main facility data from measuring instruments, IoT sensors, and PLCs and determining learning data

- Feature Extraction: Extraction of outliers (vibration, oil pressure, temperature, etc.) and selection of feature classification (tag) according to mechanical wear and tear, defects, etc.

- Machine learning: equipment load and fire anomaly model definition, machine learning through deep learning/machine learning algorithms

-